Some new additional parts arrived last week.

A bag of electonics bought on Aliexpress.

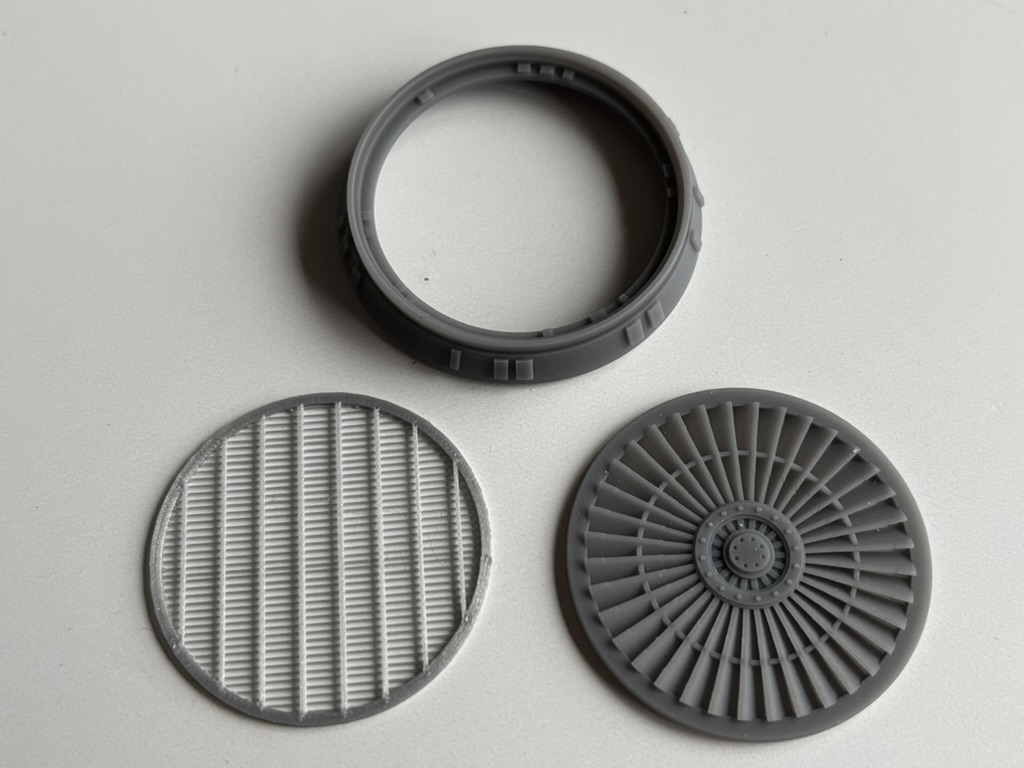

…and set of resin prints from https://www.falcon3dparts.com/

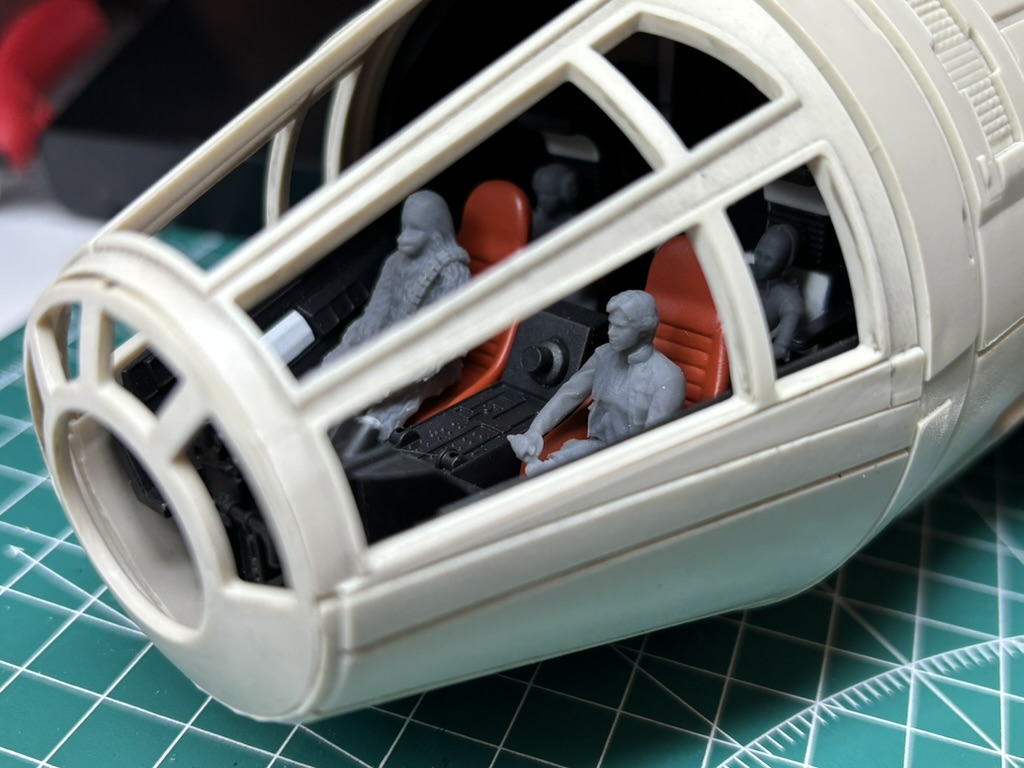

Cockpit crew:

Additional Leya figures:

Luke for gunwell:

External warning lights housings:

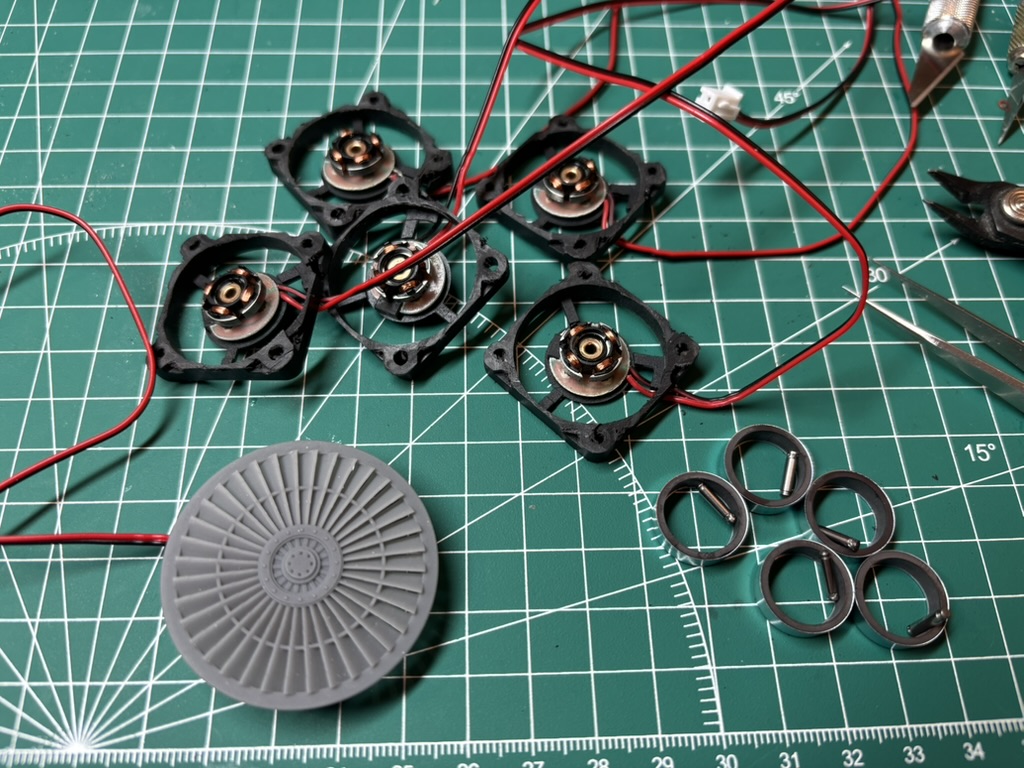

and finally set of Engine Ventilators, including fans, housings and coolshade net.

Combined together looks cool!

I’m not sure at this stage about net parts, I think photoetched parts would do better work here…. To be continued 🙂

Of course I removed quickly figures from the support resin and tried it out in the cockpit – SWEET!!!

Ok having all those fantastic goods in hand, immediately I started to plan the implementation 🙂

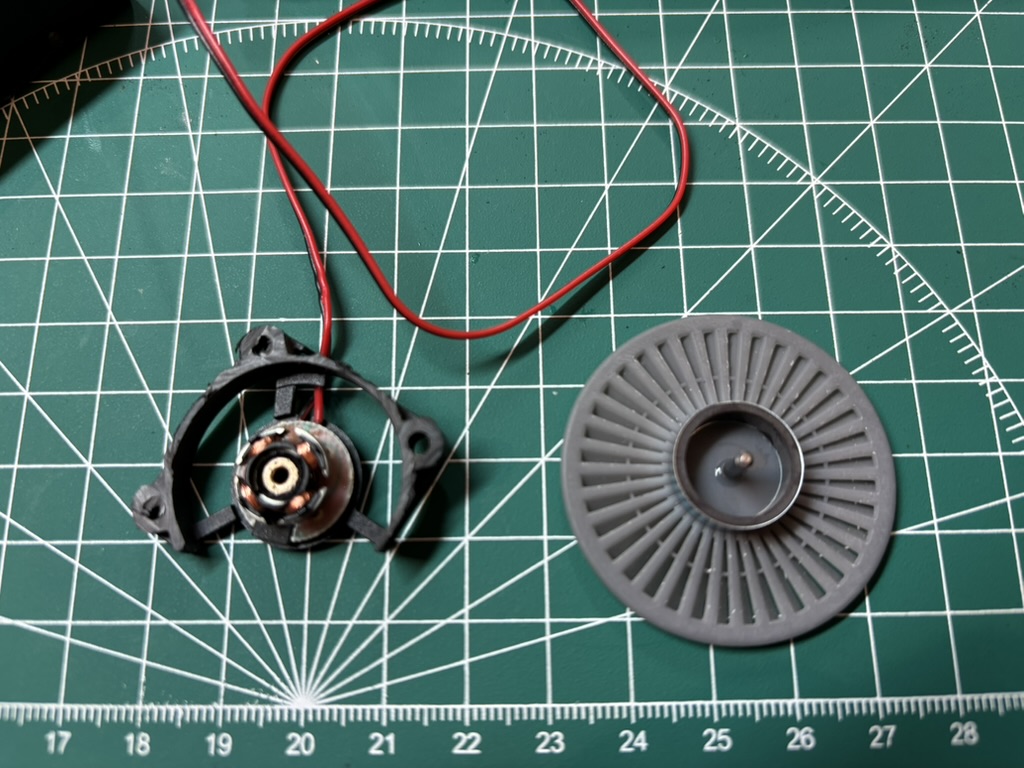

I would like to make engine ventilation fans running. For that purpose I would like to use 5V motors from 22mm “cpu fans”.

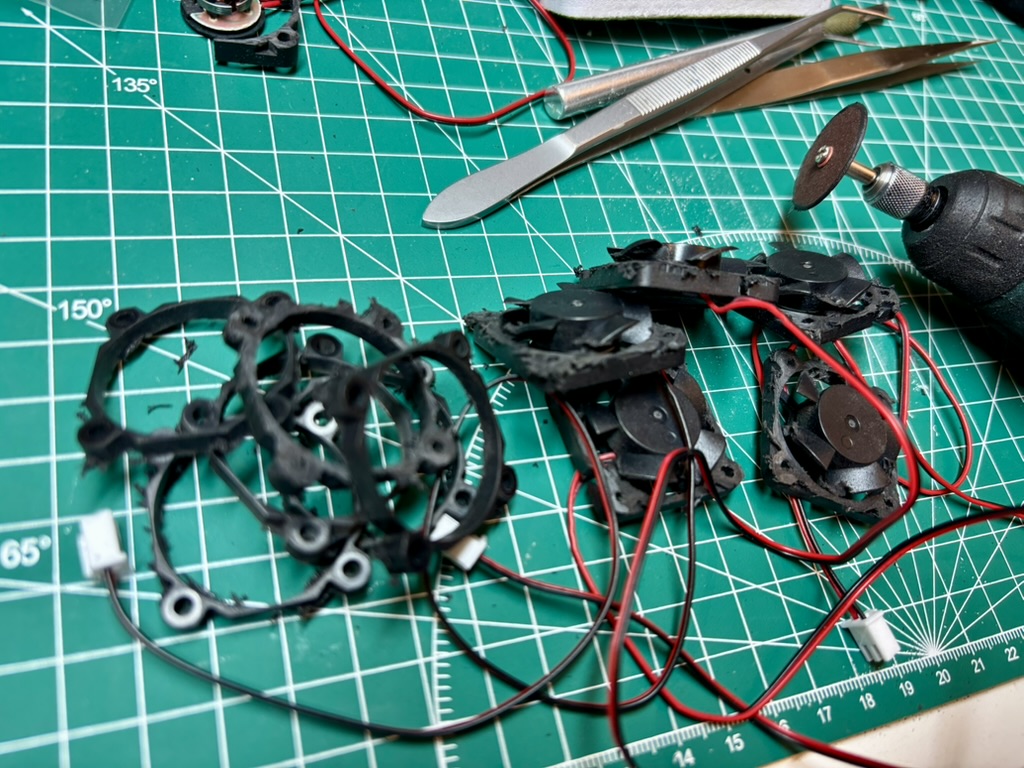

Without further ado – I went for “live prototyping on model parts”. Electric fan was stripped down, housing was cut down in half and round magnet and bolt were removed from the turbine. Quick pre-assembly, a bit of drilling in the 3d printout fan and I fixed parts building in fact new turbine out of 3dfalconfiles part.

Main challange was to align it properly, that the fan will be able to spin correctly. I used the motor itself and adjusted bolt and magnet.

It’s working!

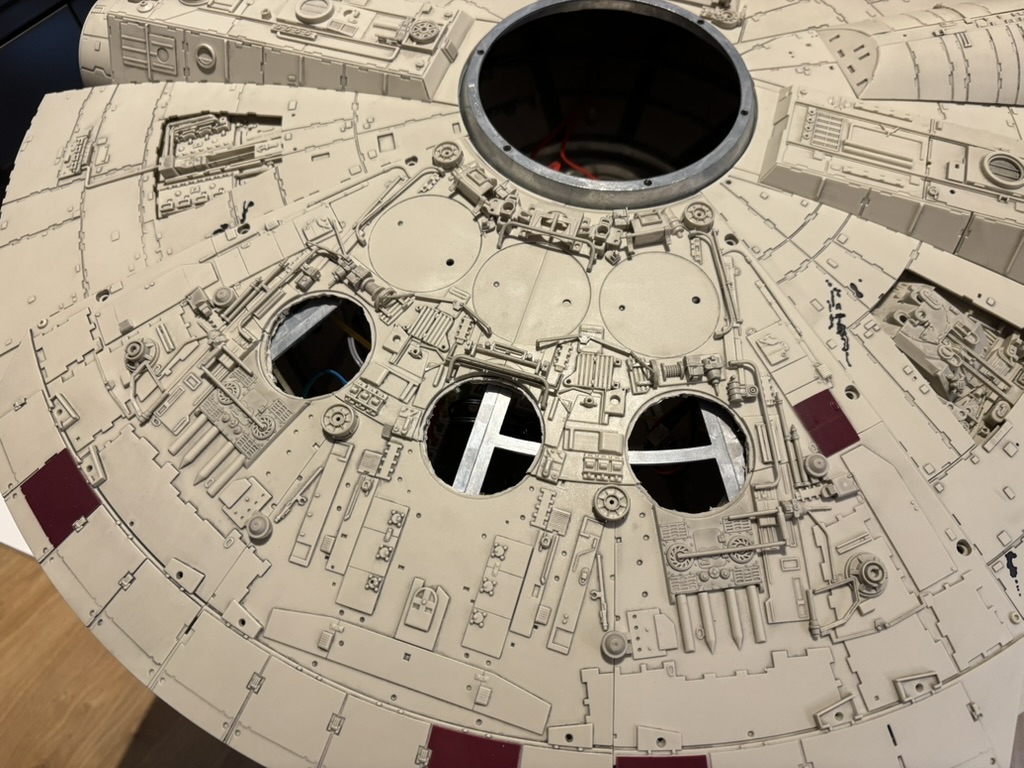

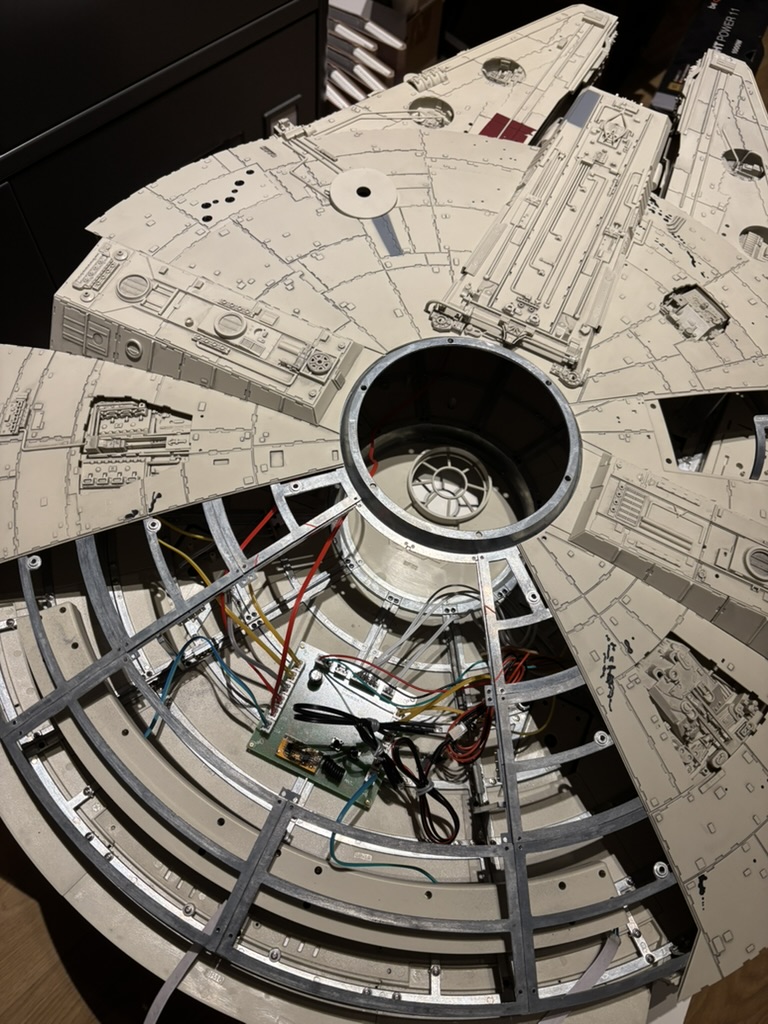

With the next step I removed a lot of plastic from engine cover plates, to cut down holes for engine ventilators.

Unfortunately, the frame need to be removed under the vents holes.

I unscrewed those frame parts, general upper saucer structure is affected but it will be straighten by final construction and should be fine / I hope 🙂

After all six openings preparation, I aligned vents housings – looks good!

After first prototype success, I went with other 5 motors preparation / electric fans destruction 🙂

Then I prepared parts for new turbines assemblies to come.

That was fun session – first session with Falcon that I went outside of the box. I believe it will bring good improvements to overall model appearance.

Stay tuned!